The Sox Factory has paved the way for direct to garment printing on socks in South Africa. Our TruePrint technology allows the printing to be infused into the socks, which means long-lasting colours that will not fade or wash out. This high-quality printed sock can be used for all types of sports, everyday comfort wear and promotional items for your brand.

How does The Sox Factory TruePrint work?

A PolyLon36 white sock is placed onto the drum of our printers, and the printer will create a seamless print around the sock continuously. Once the socks are printed, they will be taken to the oven to be “burnt” or infused into the fibres of the sock. After a round in the oven, the sock will be taken to boarding which gives it that sleek finishing look and sent to packaging.

There are countless factors influencing each sock’s colour; humidity, oven temperatures, outside temperatures, shift changes etc. We have learned to work around these elements and give our clients the best of the best.

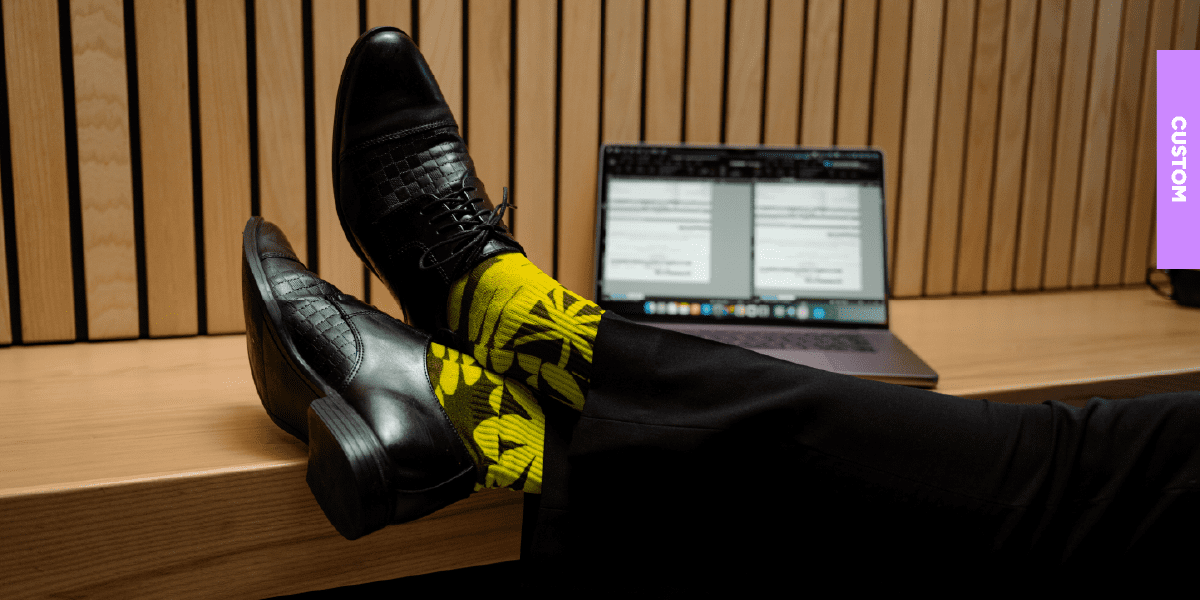

Advantages:

- Seamless print around the sock

- Does not fade or wash out

- Will not crack or expose white lines

Disadvantages:

- Limited to Polyester

How does sublimated printing work on a sock?

Usually, a white sock is placed on a printer surface and the digital printing technology uses heat transfer to apply an image to the intended substrate. When the sock is stretched around your leg the print will also stretch out and you will see white lines form in between the printed area. Sublimated printing does not allow for a seamless transition and usually is only printed on the sides, or front and back of the sock.

Advantages:

- Consistent colour

Disadvantages:

- Limited to Polyester

- Not a seamless pattern

- When the sock is stretched, lines will form

How does heat transfer work?

A design is printed on a transferable paper/sheet which is placed on the socks and then transferred by an extremely high temperature.

Advantages:

- Can be used on any material like cotton, polyester and nylon.

Disadvantages:

- If stretched, the print will start to peel or crack from the sock.